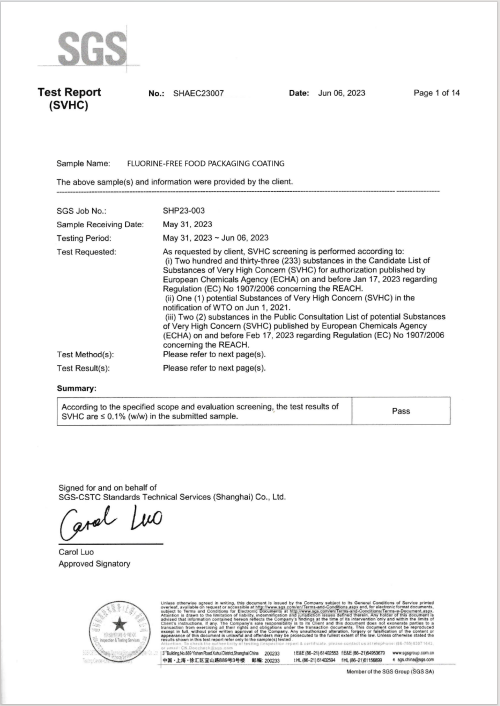

The biodegradable food-grade plastic-free coating has passed the SVHC test and biodegradation test of SGS, and it has excellent physical properties, such as heat sealing, barrier property, wear resistance, high and low temperature resistance, oil resistance, etc. It can reduce the difficulty and cost of recycling packaging materials and reduce the damage to the natural environment.

●DESCRIBE●

In order to reduce the environmental pollution of packaging, our company committed to the development of the biodegradable food-grade plastic-free coating, and through SGS testing. This product is fluoride-free coating, which can replace or reduce the plastic material on food packaging, but also enables the packaging to meet the physical performance standards of the original packaging without the use of plastic materials or reduce the use of plastic materials.We hope that through our packaging technical support, we can provide customers with plastic removal or plastic reduction packaging solutions, and are willing to provide customers with packaging solutions, product testing and samples, so that packaging can meet the standard requirements of customers.

Our coatings are tested by SGS to meet food and biodegradable standards(Click here get more detail about reports). At present, most of the degradation schemes in the market are based on compost degradation, but it increases the difficulty of recycling and the cost of degradation. Our solution is to solve the problem of imbalance between the environmental and physical properties of packaging through a naturally degradable coating. Leave your company information and contact information, we will take the initiative to contact you and provide you with free samples, after obtaining samples can be tested according to various standards on our samples. (Contact us and get the free samples,info@xtmaterial.com )

●SVHC TEST●

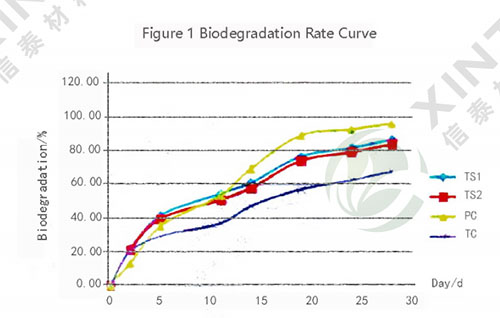

●BIODEGRADABLE●

What we do is to test the degradation of individual materials, not to improve the degradation rate by testing the degradation of finished products or semi-finished products.

------Test method

Two groups of blank control(BLK), one group of positive control(PC), two groups of test sample(TS)and one group of toxicity control(TC were set for the test.The solutions were prepared as follows:

BLK: 30 ml 3 g/L Sludge solution;

PC: 30 ml 3 g/L Sludge solution + 10 ml sodium benzoate stock solution;

TS: 30 ml 3 g/L Sludge solution + 18 ml sample stock solution;

TC: 30 ml 3 g/L Sludge solution + 10 ml sodium benzoate stock solution + 18 ml sample stock solution;

------Test resolution

------Test results

As showed in the attached table 1-3 and figure 1, at the beginning of the experiment, the content of inorganic carbon and total carbon in the culture medium were 157.3 ㎍/L and 4.26 mg/L respectively. At the end of the experiment, the total amount of CO2 evolved in the blank control group was 46.83 mg/L, and the temperature was kept between 22.1℃ and 23.4℃. The biodegradability of the positive control group was 68.77% by day 14. The biodegradability of the toxicity test group was 46.85% by day 14. The difference of extremes of replicate values of the biodegradation at the plateau, at the end of the test and at the end of the 10-d window, was less than 20%.

------Test conclusion

Under the experimental condition, the average biodegradation rate of 10-d window was 52.42%. The average biodegradation rate of the tested sample was 84.68% after 28 days.

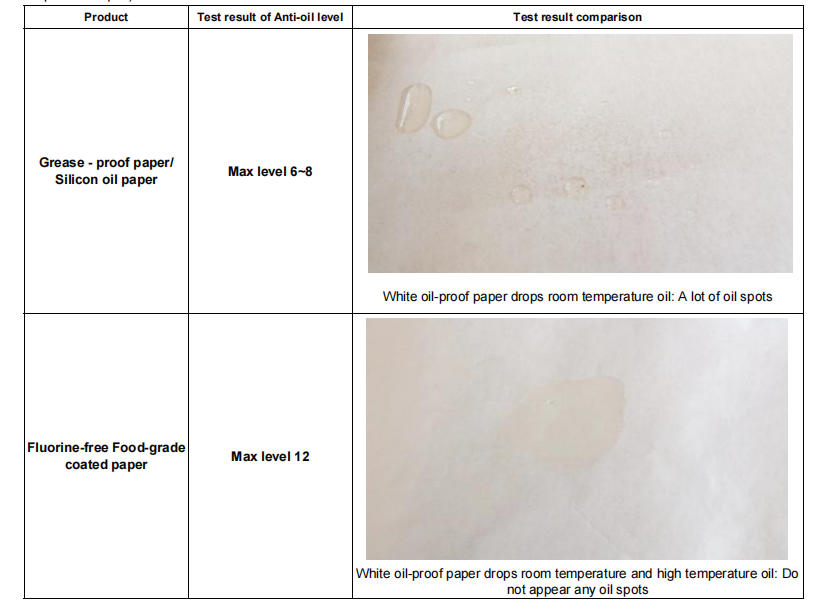

●EXCELLENT PHYSICAL PERFORMANCE●

■ Weather resistance (-30 °C to 180 °C)

■ Barrier performance (test data attached on the next page)

■ Wear resistant (face-to-face, 4 pounds, 600 times)

■ Heat sealing performance

■ No static electricity

■ Laser puncture resistance

●EASY TO USE●

■ Single component

■ Can be coated on offset/gravure printing lines

■ No need to change the original process route

■ No need to modify equipment

●CHARACTERISTIC●

★1/ Direct contact with food(Suitable for EU food grade safety standards)--- We can also provide the test report.

★2/ Suitable for EU food grade safety standards:

A ------ Liquid barrier ( high or low temperature liquid)

B ------ Gas barrier:Oxygen and Water Vapour

| Product | Water Vapor Transmission Rate (g/㎡.24H) | Oxygen Transmission Rate (cm3/㎡.24H. 0.1MPa) |

| Fluorine-free Food-grade coated paper | <10 | <10 |

Fluorine-free Food-grade coated paper with aluminium foil | <0.5 | <0.5 |

C ------ Improve paper toughness

D ------ Improve paper surface brightness

★3/ Biodegradable--- We can also provide the test report.

●APPLICABLE TO THE TYPE OF PACKAGING PRODUCT●

Paper box

(Click picture get more details)

Paper cup

(Click picture get more details)

Paper bag

(Click picture get more details)

●HOW TO GET PRODUCT PACKAGING SOLUTION ●

1.Tell us about your packaging problems, packaging requirements and packaging usage scenarios.

(Our email: info@xtmaterial.com Whatsapp: +852 63368447)

↓

2.We will put forward our suggestions and plans according to your basic situation.

↓

3.After accepting our suggestions and schemes, we will produce samples according to the schemes and deliver them to you,you can test the sample by your standard.

↓

4.We can provide you with finished packaging production or provide you with raw materials to produce finished packaging in your local factory.

THE DETAIL TEST REPORT :

Contact: Mason

Phone: 13049135834

Tel: 86-13049135834

Email: info@xtmaterial.com

Add: 2nd Floor, Block D, No.2 Sanhuan West Road, Shishan Town, Nanhai District, Foshan City, Guangdong, China

We chat